1. Overview:

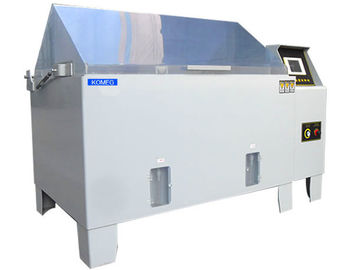

Salt spray corrosion test chamber (Salt spray test chamber, salt box, salt spray test machine, salt spray corrosion test chamber) can be used to assessing the ability of salt spray corrosion resistant materials. It can be used to assess materials’ protection layer resistance capacity to salt spray corrosion, whether you are testing hardware industry, screw industry, electroplate industry, automotive and motorcycle parts, communication industry, computer industry, electronic industry, coating industry, research institution, etc. Our salt spray test chamber can offer you a best solution. Due to the increasingly harsh environment, Salt Spray Tester becomes more and more popular. Salt Spray Tester has been the most hot-selling products these days, for the fast delivery time and reasonable price of Salt Spray Tester.

2. Standards Implemented and Met

KOMEG salt spray corrosion test chambers are cost effective and are capable of complying with the most popular international standards for salt fog testing including:

1 GB/T 2423.17-1993 salt spray test

2 GB/T 2423.18-2000 salt spray test

3 GB/T 10125-1997 salt spray test

4 ASTM.B117-97 salt spray test

5 JIS H8502 salt spray test

6 IEC68-2-11 salt spray test

7 IEC68-2-52 1996 salt spray test

8 GB.10587-89 salt spray test

9 CNS.4158 salt spray test

10 CNS.4159 CASS Copper accelerated acid salt spray test

11 GB/T 12967.3-91 CASS Copper accelerated acid salt spray test

3. Features

1, Interior and exterior use hard PVC, anti-corrosion, anti-aging with smooth and beautiful surface

2, Cover use hard transparent PMM or hard PVC, can view specimen status anytime

3, Fine glass nozzle ensures uniform diffusion of spray and not being blocked by crystal, which further maintain standard and quality of continuous test.

4, Spray time is adjustable

5, High precision temperature controller with digital display introducing P.I.D. automatic tuning control.

6, Double over heating protection and low water level alarm ensures operation safety.

7, Demist function: water sealed chamber cover

8, Comply with international standard like ISO 9227, ASTM B117, CNS, JIS, DIN, GB, BS, IEC, MIL, etc.

4. Installation Requirements

All KOMEG chambers require the following:

A clean, oil free compressed air supply to atomize the salt water into fog.

Either pressurized or manual de-ionized water supply for making up the salt water solution.

Single phase 220VAC with earth ground.

Connection to an exhaust vent to atmospheric pressure and a low level waste water floor drain.

5. Introduction

KOMEG offers the newest and most modern salt fog testing chambers for your testing requirements. KOMEG salt spray test chambers are offered in 60 Liter, 270 Liter, 800 Liter and 960 Liter models and are cost effective solutions to accelerated corrosion testing of samples in salt fog. Models have an uncomplicated design that has optimized the open area to maximize the number of test coupons while providing headroom for testing large and bulky objects.

6. Specifications

| Model |

HL-1000-SS |

HL-160-NS |

HL-90-BS |

HL-60-SS |

| Interior dimensions(W*H*D)mm |

1600 x 600 x1000 |

1600 x 500 x1000 |

900 x 500 x 600 |

600 x 400 x 450 |

| Exterior dimensions(W*H*D)mm |

2250 x 1360 x 1220 |

2240 x1500 x1600 |

1460 x1280 x 910 |

1130 x1070 x 630 |

| Volume(L) |

960 |

800 |

270 |

60 |

| Heater |

15KW+1KW |

15KW+1KW |

7KW+0.75KW |

3KW+0.75KW |

| Air compressor |

3HP |

2HP |

1/2HP |

1/2HP |

| Temp. range |

35ºC~50ºC |

| Power |

AC220V 1Φ 50Hz |

| Test Applicable |

NSS, ACSS,CASS,CORK |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!