1. At first, Know the following Typical coatings that can be evaluated with this method are:

1) Phosphated surfaces (with subsequent paint/primer/lacquer/rust preventive)

2) Zinc and zinc-alloy plating (see also electroplating). See ISO 4042 for guidance

3) Electroplated chromium, nickel, copper, tin

4) Coatings not applied electrolytically, such as zinc flake coatings according to ISO 10683

5) Organic coatings

6) Paint Coating

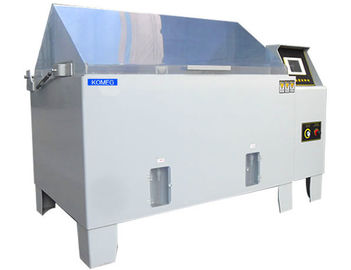

2. Salt Water Spray Tester's Application

Salt water spray test chamber is widely used in Corrosion resistance test for products after treated by plating, anodized, spraying, and anti-rust, to test the surface treatment of various materials. Those so-called treatments include coating, electroplating, and films of organic and non-organic materials, anodizing, anti-rest oil and corrosion resistant treatment, which may achieve the purpose of keeping the items from being corroded for a longer period.

3. Standards implemented and met:

1) GB/T 2423.17-1993 salt spray test

2) GB/T 2423.18-2000 salt spray test

3) GB/T 10125-1997 salt spray test

4) ASTM.B117-97 salt spray test

5) JIS H8502 salt spray test

6) IEC68-2-11 salt spray test

7) IEC68-2-52 1996 salt spray test

8) GB.10587-89 salt spray test

9) CNS.4158 salt spray test

10) CNS.4159 CASS Copper accelerated acid salt spray test

11) GB/T 12967.3-91 CASS Copper accelerated acid salt spray test

4. If you are new to Salt Spray Tester, you need to know the Features:

1) The whole part of the device is made of P.V.C. Sheet and the inside of the device is reinforced by using a special lining material. Hence, it is sturdily made and will not transform forever.

2) The test chamber is heated from five directions in order to ensure the temperature difference in the chamber may be kept within (± 1℃).

3) Spray nozzle: The nozzle is specially made to enable it to suck up the salt water and then spray it out in the shape of mist with considerable high speed. When it falls on the surface of the item being tested, the difference of fallen mist may be controlled within ± 0.3ml / 80 cm2h.

4) HUNTER PRINCIPLE is used to make the saturated air hot and moist and to keep the humidity in the test chamber required for test.

5) Temperature is the pre-requisite condition that with have direct impact on corrosion rate. We use P.I.D. temperature control unit to limit the temperature difference within the range of ± 0.5℃.

6) A warning device is used to indicate the low level of the test fluid, when the fluid is only enough for being sprayed for five hours, a buzzer will remind the user to replenish the liquid to ensure continuous spray test.

7) Use full automatic detecting system, test stopped automatic, and lighting display when trouble.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!